15 Fetter Lane, EC4A, London. Brise Soleil, tapered column and canopy in Chocolate PVD stainless steel V-Grooved and folded to appear as solid bronze.

Architects: McBains Cooper

Client: British Steel Pension Fund Trustees Ltd

Fit-out: Nucom Interiors

PVD stainless steel & fabrication: John Desmond Ltd

Photography by Paris Granger

Creating a new and dynamic identity for a leased office building

Elizabeth Humphries, Associate Director Architecture at McBains. Elizabeth was the architect for this project.

“The original brief was to undertake renovations to dilapidations as the main tenant was moving out of the building then McBains were asked to provide architectural services to refresh all the internal common parts and a concept design for the external entrance.”

“The existing entrance was low and dark and not very discernible from the main thoroughfare as the entrance was at the side of the building. The client wanted to create a clear entrance that was welcoming and that had more gravitas and appeal.

There are some very smart façades along this stretch with some buildings having cathedral-like reception areas. Our design is intended to give the impression of a double height reception even though it is single height. We created a design that unified the façade at ground and first floor levels to give the impression of a more impressive space within”

Challenges

There were quite a few challenges on the project. Firstly we did not really know the structure of the façade of the building as there were no detailed records or drawings. Assumptions were made as to what would be found once the existing façade was stripped off. These assumptions proved entirely false as the slab edge was much further back than assumed. So the project was structurally challenging. Another challenge was that we had to fix the canopy whilst the tenants were in situ whilst we were working.

Also there were a lot of trades people involved which meant a huge amount of co-ordination. There were curtain wallers, people replacing the glazing, revolving door fabricators and installers and stone masons who constructed the stone column.

The exterior specification

“Originally much brighter finishes were proposed ie a powder-coated polyester canopy but the planners were not in favour as there is a listed building opposite and the bright finish was deemed to be unsuitable to be in such close proximity.

So we had to consider a more traditional finish. We looked at a bronze-coloured material, Granex 6WL electro-plated and sandblasted stainless steel that had been used elsewhere to good effect and it had the really contemporary feel that we wanted. However we were really concerned that the electro-plated finish would be adversely affected by weather and we could not obtain a guarantee from the manufacturer.”

PVD stainless steel as a finish

“When Alex, from John Desmond, proposed PVD as an alternative this proved more than acceptable as it had both the aesthetic appeal of bronze and also had a twelve-year guarantee which gave us and the client much-needed reassurance. The V-Grooving and folding of the PVD stainless steel sheet meant we would achieve the look of solid bronze without the weight and this specification was approved by the planning council.”

Nucom appointed John Desmond so we hadn’t known of them before. Alex worked hard to coordinate the sub-contractors which was not an easy process as well as helping us with the eventual specification. I didn’t know about PVD before so it has been an education but I like it and I will use it again for fit out projects.”

Commercial success

“We have worked with the client a few times but not to this extent, this was our largest project with them to date. The client was thrilled with the result. Why? They pre-let one of the floors whilst the work was still going on and quickly had considerable interest in the other floors. They have also significantly increased the rent charged on the spaces.”

Talk to us about V-Grooving for your project

Creating a desirable building with a contemporary façade

Alex Pashouros is Project Manager at John Desmond Ltd, fabricating and installing the brise soleil, canopy and tapered column.

The building really needed a strong identity as it was dated and lacked visual impact when viewed from the thoroughfare.

The design of the brise soleil, canopy and column was developed to create a sense of presence and to bring the building into the 21st century in terms of style and materials. The re-orientation of the entrance to Fetter Lane and away from the side again gives the building greater appeal and is much more inviting.

An appearance of solidity without being solid

The original specification for the brise soleil fins was for solid stainless steel bar so it was clear that the architect wanted the substantial look that of solid material. The issues with using solid stainless steel were that it would have been very heavy to hang from the canopy and the fins would have deflected under their own weight. As this would have still needed to be clad to achieve the bronze look it would have been an expensive exercise in terms of achieving the finish and attaching such a weighty structure to the building.

We were keen to offer an alternative that had the same substantial appearance but that would be much lighter and a lot less expensive to produce both in terms of the material and the structural labour.

V-grooved and folded sheet to replicate solid stainless steel

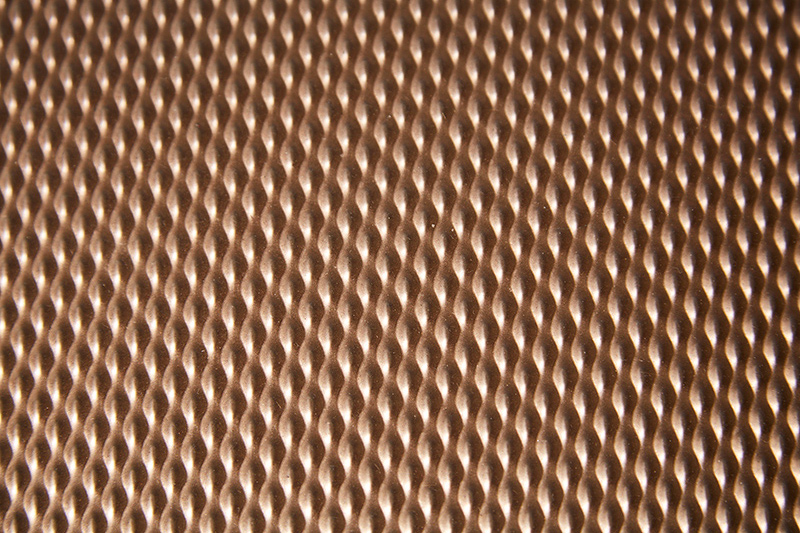

The solution we felt was both cost-effective and aesthetically a perfect match was to fabricate the brise soleil, canopy and column from PVD coloured stainless steel. This would then be V-grooved and folded to appear as solid material. The colour we proposed was Chocolate as this has the appearance of a rich bronze. The original specification was for a textured finish and we offered an embossed finish SB-H25.

See other examples of V-grooving

Modular build off-site to reduce risk

There were challenges on the project as we couldn’t have free access as the remaining tenant had sensitive legal documentations in its care. All work had to be carried out from the outside of the building other than two weekends and our normal access to the building interior was via scaffolding that was wrapped around the outside. With such restricted timescales and access it was essential that whilst on site all construction work proceeded smoothly and without any delays.

Building off-site was the only way to approach this project as by completely building the structures off-site this reduced the risk of on-site delays and disruption.

All components were fabricated in our workshops which allowed the structures to be inspected by the design team and the contractors.

The architect’s design enabled the canopy to be made off-site. The cladding was clipped on using bespoke clips in the workshop and then dismantled into as few sections as possible. This process meant that all the clips and sections were in the right places and the on-site process was greatly simplified. A hoist on site was to lift each section into position however its weight restriction was 250kg. And so the canopy structure was transported to site in 26 sections each weighing 150kg.

The brise soleil was built to its full height of four metres in the workshop, then dismantled and taken to site. The brise soleil verticals were solid with aluminium inserts clad in the PVD sheet. The fins were created from the PVD sheet and strengthened with stainless steel ribs which were bonded on together with the end caps.

The column however was six metres high so had to be built in two sections. It was laid down on its back and the whole column clad in the workshop before being dismantled and taken to site.

For the brise soleil, canopy and column 45 sheets of 2.4 by 1.2m 316 1.5mm stainless steel were used with the sheets coloured through the PVD process and then embossed. Our fabrication time was four weeks and the installation time eight weeks.

Call Alex on +44 (0) 20 8946 8295 to discuss your project

Working with a tenant in-situ

Neil Cook is Project Manager at Nucom Interiors.

Neil says “The primary tenant, Bird and Bird, at 15 Fetter Lane had their own building built for them and moved out which, frankly, left a tired building. The objectives were to create Cat A office floors, refurbish the reception and a new enhanced area by relocating the entrance doors to Fetter Lane from W Harding St. We were also to wrap a canopy around the building and drop a thin limestone column with backlit signage. The aim was to grab attention from the main highway and give the building greater street presence and impact. There was a key challenge in that a tenant remained in situ for the entire installation time.”

“The build process was a complicated arrangement as there were seven trades involved. Drawings were produced in conjunction with the structural engineer Steve Cockayne. The challenge was securing the sub-structure steelwork frame to hold the cladding.

A great deal of attention was given to the scaffolding design in order to facilitate exterior works. We only had access from this to the building.

I did know JDL from some years ago and, I don’t give praise lightly, they really do know what they’re talking about. The finishes were specified achieving the look the designer wanted and the PVD looks good, it’s a nice aesthetic.”

Illuminating the structures

Tom Portman-Smith of Arena Electrical Services Ltd was the project manager for all of the electrical works at Fetter Lane.

Tom says “Our involvement with John Desmond was through the large canopy which had integrated lighting. A container was created at the side and top of the cavity to accommodate the electrics. There were six electricians on our team which I headed up and liaised extensively with Alex whose skill ensured the project ran very smoothly which is a pleasant change. I really liked the way the LED lighting complemented the PVD stainless steel”.

Email Alex for a sample of PVD coloured stainless steel in Chocolate with embossed finish SB-H25.

For the brise soleil horizontals stainless steel sheet is clad around a timber core giving the impression of solid bronze fins.

15 Fetter Lane, EC4A, London.

PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger

The brise soleil comprising sheet materal clad around a timber core, giving the impression of solid bronze fins.

15 Fetter Lane, EC4A, London.

PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger

The new entrance façade.

15 Fetter Lane, EC4A, London.

Bronze PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger

The brise soleil fins being created in the workshop with stainless steel rib strengthening.

15 Fetter Lane, EC4A, London.

Architectural metalworks and PVD by John Desmond Ltd.

Showing the inset LED lighting to the PVD stainless steel column.

15 Fetter Lane, EC4A, London.

PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger

Showing the inset LED lighting to the PVD stainless steel column and the texture of the SB-H25 embossed finish.

15 Fetter Lane, EC4A, London.

PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger

The canopy and column V-grooved from PVD stainless steel in Chocolate, giving the appearance of solid bronze.

15 Fetter Lane, EC4A, London.

Bronze PVD coloured textured stainless steel in Chocolate for Brise soleil, canopy and column.

Architectural metalworks and PVD by John Desmond Ltd.

Photography by Paris Granger