Specialist Metal Finishes

Planters and architectural metalwork in patinated brass, 54 Bedford Gardens, Notting Hill, London, UK

Client and main contractor, Bancroft Heath

Architect: Nash Baker

Interior Designer: Desalles Flint

Architectural metalworks, and specialist metal finishes: John Desmond Ltd.

Specialist metal finishes

Complementing our architectural metalwork we have developed a range of distinctive finishes for stainless steel, brass and other materials, a selection of which are shown below along with examples of projects into which they have been specified.

Combining specialist finishes with textures, folding and laser-cutting

The specialist finishes and methods can be combined to create further intricate and unusual applications. For example, the PVD colouring process can be used on textured stainless steel, patinated brass can be laser-cut and V-grooved material can be powder-coated.

Contact Alex to ask about specialist metal finishes and how to combine them to create distinctive effects at [email protected]

Bespoke metal finishes

We offer a range of specialist finishes however sometimes our clients want a finish that is unique to their project. It maybe to convey the brand of their client, the identity of the building or for other special reasons. We work with interior designers and architects to develop finishes that are exactly what they are seeking to utilise in their project.

Cost-effective alternatives to solid materials

If value-engineering is needed – and if the specification is originally a material such as bronze then value-engineering often IS needed, then we can help with proposals, mock ups and samples of alternative materials and methods that will be a lighter weight, more cost-effective and that produce less waste material.

Materials, finishes and coatings

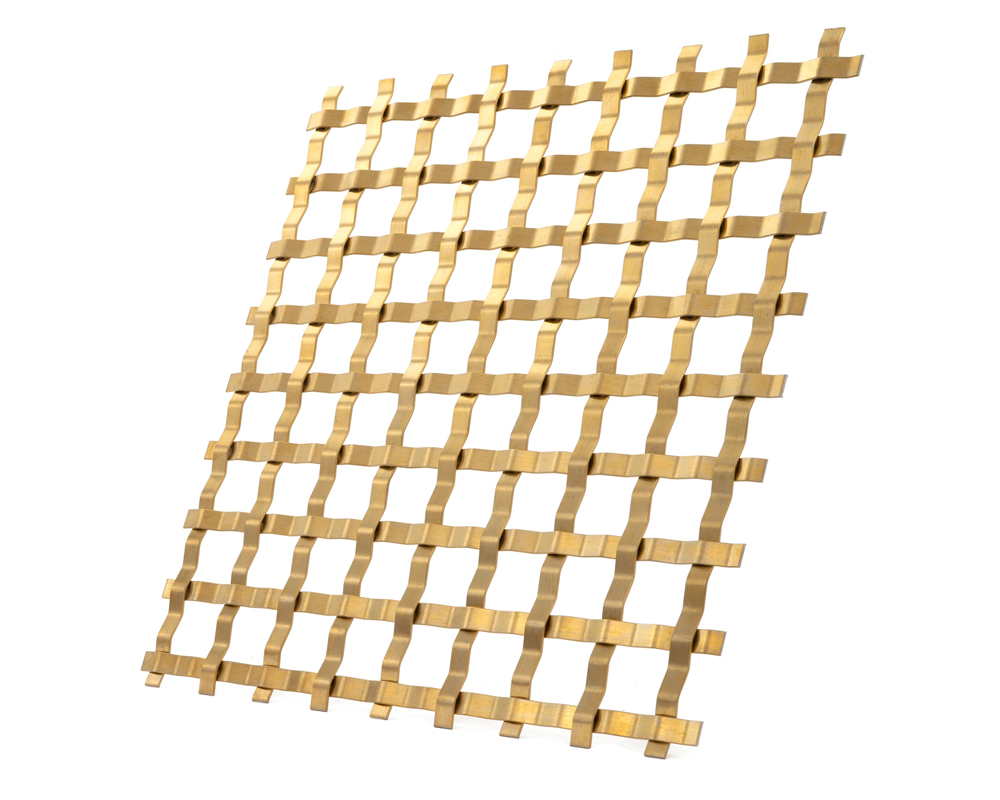

PVD coloured stainless steel architectural mesh

Stainless steel Architectural Mesh is a strong and relatively lightweight product specified for interior and exterior applications. Brass and copper mesh, for example, can be replicated through the PVD process with a resulting product that will not tarnish or age.

See a range of mesh designs and applications and PVD colourways

PVD coloured stainless steel

PVD coloured stainless steel is a sustainable alternative to anodising and electro-coating both of which involve chemical baths. The PVD process uses heat and gas and produces no chemical waste products.

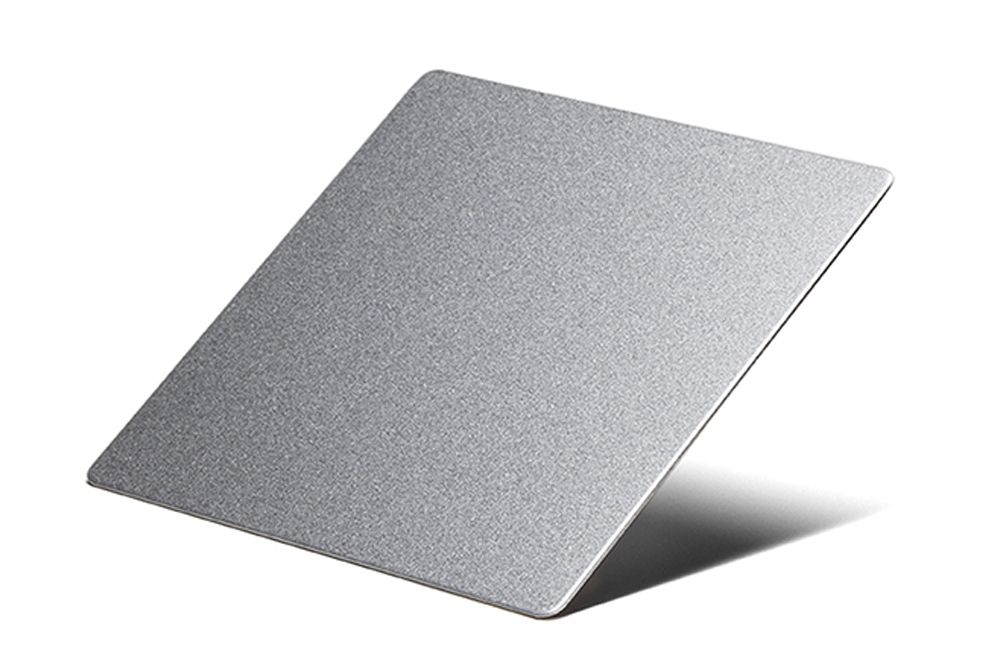

Textured stainless steel

Textured stainless steel brings another dimension to specifying PVD coloured stainless steel. The range of embossed, surfaces provide tactile qualities as well as reflecting light in subtle ways which add to the creative possibilities when designing with this material.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel.

Cor-ten – Accelerated finish

Corten, also known as weathering steel, is designed to develop a rusty patina, making it corrosion-resistant and requiring no refinishing. John Desmond Ltd has developed a technique to expedite the patina formation process, enabling fabrication within commercial timescales.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel

Patinated Brass

Left untouched, all brass would develop into patinated brass. However ready-patinated brass, created by John Desmond Ltd, already has an aged, richly-toned surface. This finish is stabilised with the application of a natural sealant making it suitable for interior and exterior applications.

Contact Alex via [email protected] to ask about a Cor-ten finish for your project.

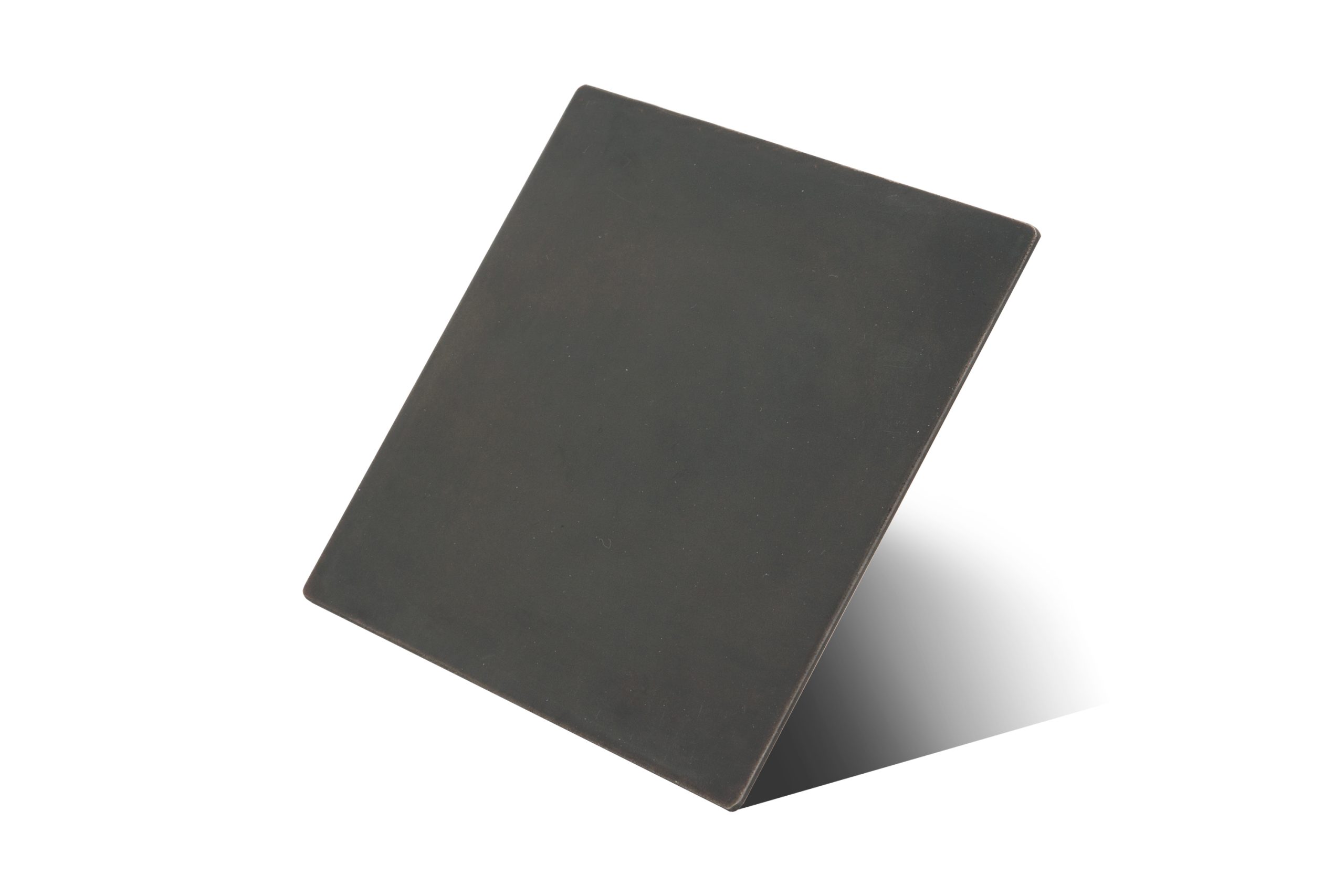

Blackened stainless steel

The blackening of stainless steel actually increases its corrosion-resistance however is mostly specified for its gleaming appearance not easily achieved through other methods. A natural wax finish is applied which maintains the burnished look yet allows the material to patinate over time.

See how blackened stainless steel creates a dramatic staircase at Google headquarters

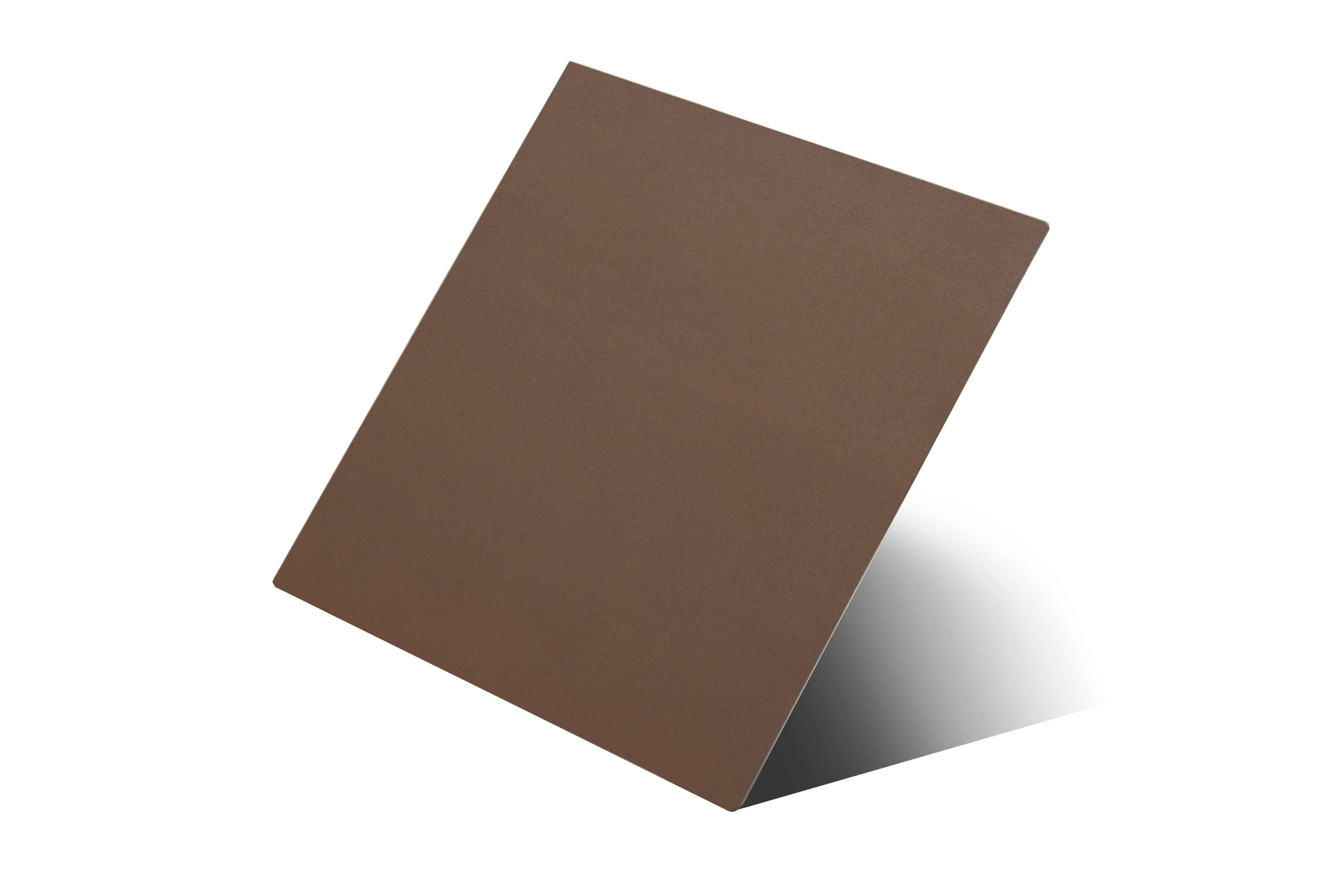

Marron powder-coat

The powder-coat colour Marron is an interesting extension to the range of John Desmond Ltd’s metal finishes. It has a bronze, metallic appearance and is a cost-effective way to achieve a rich, bronze finish for items such as planters.

Contact Alex via [email protected] to ask about Marron powder coat.

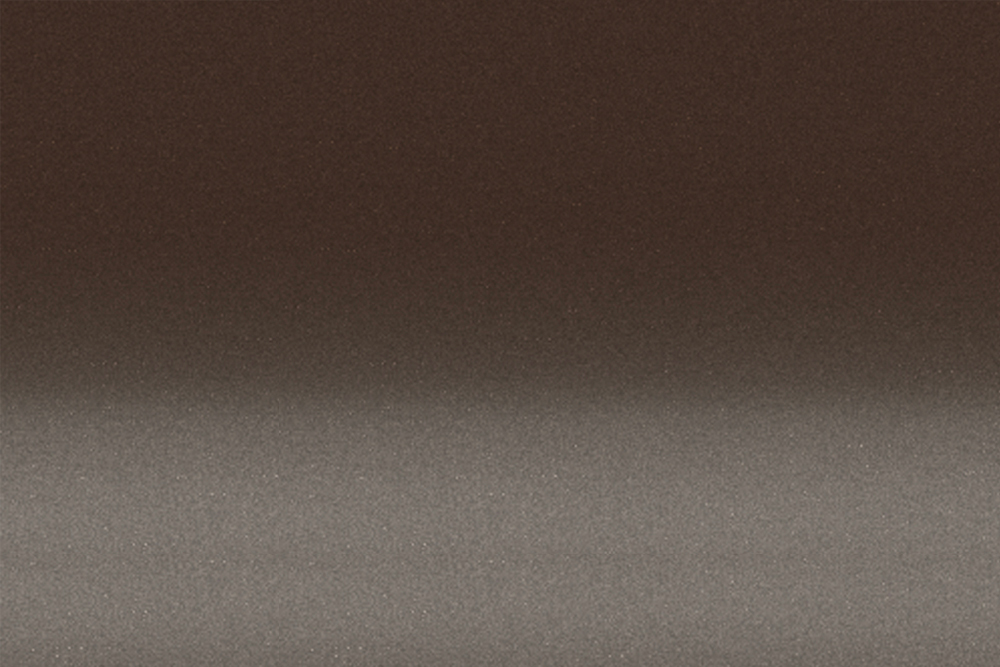

Vibration stainless steel

Vibration finish stainless steel is a versatile finish for stainless steel being non-directional and relatively non-reflective making it particularly suitable for exterior cladding. It is one of a range of finishes on stainless steel, including shot-peening and bead-blasting, offered by John Desmond Ltd.

See PVD coloured stainless steel in Vibration and other finishes and order a sample.

Shot-peened stainless steel

Shot-peening, also known as sand-blasting, increases the longevity of steel and is commonly used for aeronautical components. However it also has an interesting and versatile non-directional appearance and is consequently specified for its aesthetic as well as its relative non-reflectancy.

Find out more about shot-peened steel and stainless steel, call Matt on 020 8946 8295

Anodised aluminium

Aluminium is a lightweight, corrosion-resistant and relatively inexpensive material. Through the process of anodising aluminium can be transformed into a range of around ten coloured finishes.With the application of powder-coating an extensive range of metallic and solid colours can be achieved.

See the domed gold anodised aluminium ceiling at Wood Lane Underground Station

Laser-cutting

The laser-cutting of stainless steel, combined with PVD colouring and V-grooving provides a multitude of creative possibilities for interior and exterior applications. Laser-cutting can be used to create intricate patterns for items such as cladding, screens, balconies, balustrades and planters.

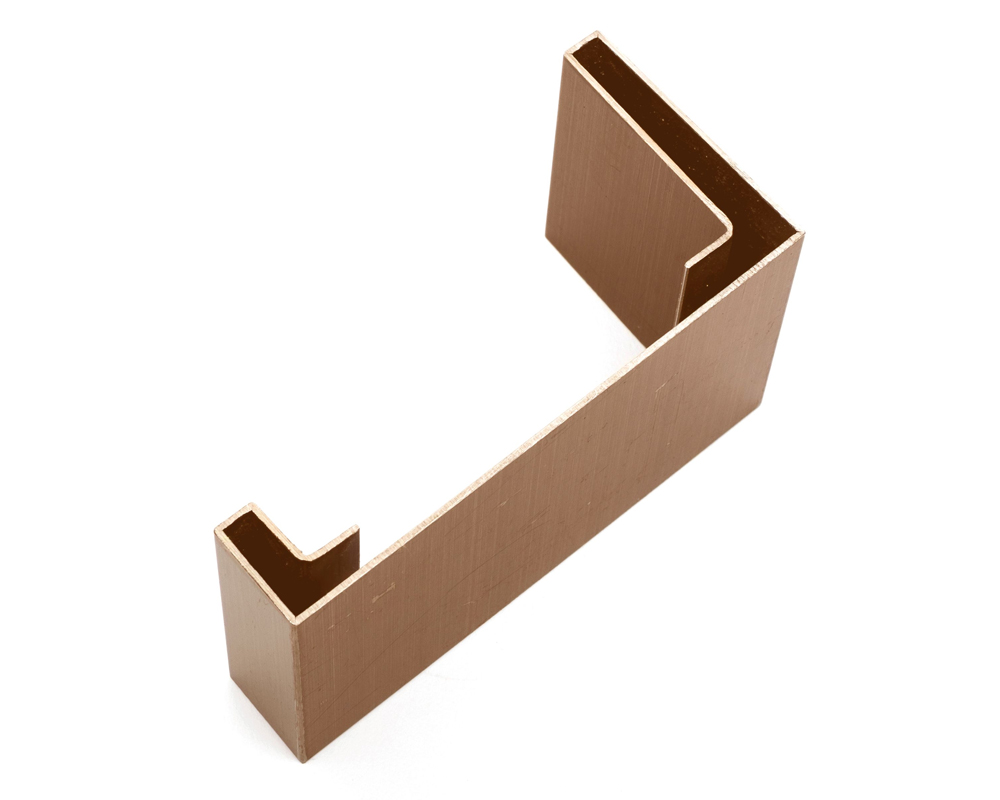

V-grooving and folding

V-Grooving and folding of specialist or laser-cut material adds to the design possibilities for very finely crafted and intricate metalwork.

This process facilitates sharp bends which replicate solid bar material whilst being lighter, less expensive and easier to work.

Anodised gold aluminium ceiling and shot-peened stainless steel cladding to ticket hall.

Wood Lane underground station for London

Underground in partnership with Westfield

Architectural metalworks, platform seating, John Desmond Ltd.

Main contractor: Costain

Architect: Ian Ritchie architects

Principal engineer: Waterman Civils

Domed gold ceiling to main traffic area in new London Underground station

A striking ceiling achieved by anodising aluminium to a pale gold colour. Aluminium is a good material to use for ceilings as, apart from its relative light weight, it is sound-absorbent. Additionally it does not rust so negates the need for extra sealants and maintenance.

The process of shot-peening, used on the stainless steel wall-cladding, created a finish that is visually non-directional and that has strengthened, or work-hardened, the stainless steel in the process.

Contact Alex to find out more on anodised aluminium for your project on [email protected]

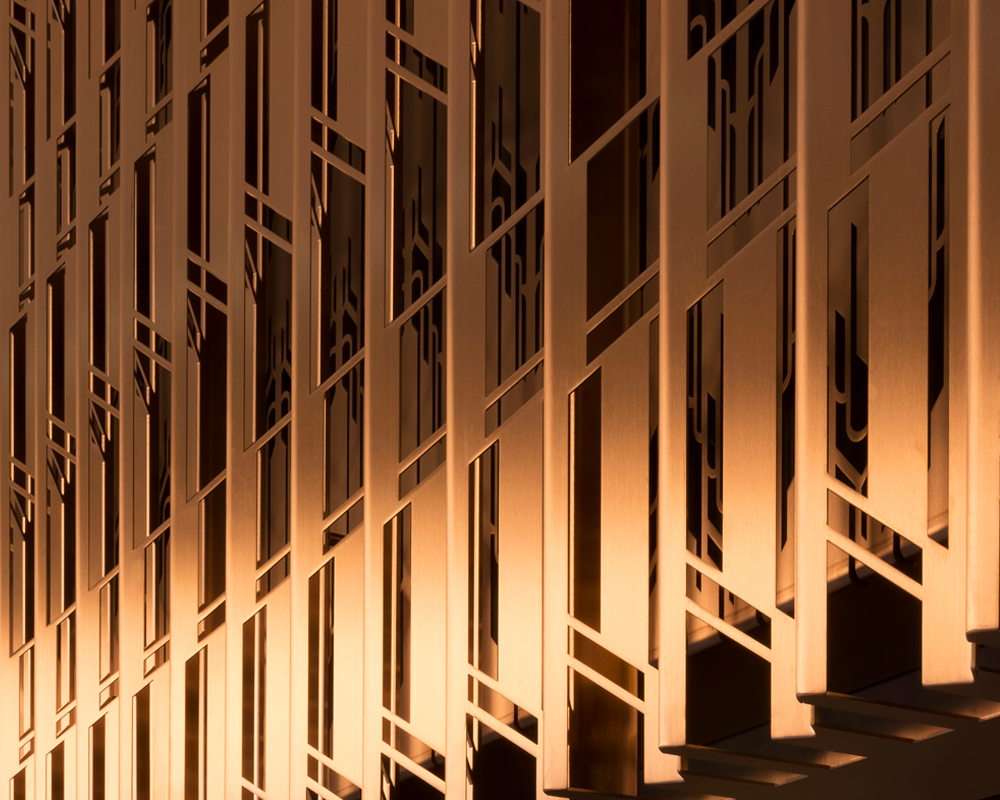

Laser-cut, V-grooved and folded PVD coloured stainless steel forming interior cladding around lift shaft.

The Gaslight Building, 29 – 35 Rathbone Street, London

Developer I.S.A Holdings

Interior architecture and design: bureau de change design office

Architects: dMFK Architects

Laser-cut PVD coloured stainless steel in custom Bronze Hairline for stairs, lift core and architectural detailing by Double Stone Steel in partnership with John Desmond Ltd.

Photography by Gilbert McCarragher

Spectacular laser-cut, V-Grooved PVD coloured stainless steel stair balustrade and lift-core

This interior lift shaft cladding and stair balustrading combines three finishes and treatments to create a multi-layered and faceted cladding. The intricate and subtle pattern and surface changes with different light and angles, creating an unforgettable centrepiece to the building.

The three-layered screening was meticulously designed and developed to the millimetre to dovetail with the existing stair treads.

Detail of overhead bar rack in the Brasserie created from V-Grooved PVD stainless steel in Champagne Mirror.

The Devonshire Club Hotel, 5 Devonshire Square, London EC2M 4WJ

Interior Design: March & White

PVD coloured stainless steel: John Desmond Ltd

Statement overhead glass rack for the exclusive Devonshire Club Hotel

Overhead glass racks have become an important part of the status and welcome that a bar gives to its customers and are often a “statement” element to bar design. Combining practicality with being aesthetically desirable this glass rack is a striking centrepiece for the Brasserie bar in this highly exclusive hotel. The material is gleaming Mirror stainless steel coloured Champagne, a soft gold, through the PVD process and then V-grooved and folded to appear as solid material.

This PVD finish was used throughout the hotel creating a harmonious, “suited” range of fixtures and furniture.

Brise Soleil, tapered column and canopy in Chocolate PVD stainless steel V-Grooved and folded to appear as solid bronze.

Office building, 15 Fetter Lane, EC4A, London

Architects: McBains Cooper

Client: British Steel Pension Fund Trustees Ltd

Fit-out: Nucom Interiors

PVD stainless steel & fabrication: John Desmond Ltd.

Upgrade of office building façade using textured stainless steel

Three finishes and treatments were applied to create the retro-fitted façade comprising brise soleil, column and cladding.

This building needed a significant upgrade to bring it up to its surroundings and to achieve the rent revenue desired by the client.

PVD coloured textured stainless steel was used as the cladding material which was V-grooved and folded to give sharp outlines to the column and brise soleil fins.

The brise soleil fins were formed from timber and clad with the textured PVD stainless steel to create a relatively lightweight solution.

Staircase in blackened stainless steel with over-wax finish for Google headquarters.

Google offices, 6 Pancras Square, London, UK

Architects: AHMM

Main contractor: ISG

Staircase fabrication, installation and finishing: John Desmond Ltd

Structural engineers for John Desmond Ltd: AECOM

Photography by Tim Soar

Retro-fitted Blackened stainless steel staircase with natural over-waxed finish

The decision to use blackened stainless steel was a departure from specifying a more shiny, corporate-looking material and John Desmond Ltd worked with the designers to create the exact “blackness” required to create this dramatic staircase.

As part of Google’s Biophilic approach to its office design its architects wanted a finish that develops a patina and ages and changes with time, not a fixed appearance that would result from using a synthetic polymer-based sealant.

The natural wax creates a protective layer to the stainless steel but allows it to age.

Helical staircase balustrading in JDL Amron PVD Architectural mesh IPZ-56 in Champagne with solid framing also in PVD coloured stainless steel in Champagne.

Offices, 22 Bishopsgate, London

Client: THB Group Insurance

Architect: T.P.Bennett

Key contractor: James Engineering

Mesh product: JDL Amron PVD Architectural mesh

PVD coloured stainless steel mesh balustrade to sweeping retro-fitted staircase connecting two office floors

The openwork of the mesh gives an airy feeling to the balustrade and staircase as it descends from the upper floor of this two storey leased section of the building.

The use of a mesh in the pale gold coloration is a contemporary departure from a traditional brass or a more industrial natural stainless steel. This material was continued through the offices with the use of floor and ceiling mounted screens demarcating work zones from meeting space.

Find out more about PVD coloured stainless steel architectural mesh