Cladding for interiors and exteriors

Harvey Nichols retail department store, The Avenues, Kuwait.

Undulating façade, columns and detailing in Double Stone Steel PVD colored stainless steel Royal Gold Mirror.

Client: Four IV Interior Design

Architect: Gensler

Developer: Mabanee

Interior and exterior cladding

A tired building façade means a downgrading of revenue achievable from rents. The introduction of canopies, columns and cladding can transform the look of an insignificant building and give it street-presence and gravitas.

Interior cladding can be utilised for a number of reasons. Cladding an interior wall can effectively mask a lumpy and imperfect wall surface as well as providing a focal or artistic feature.

Cladding, often called curtain-walling or sidings, is an effective way to protect a building’s exterior from weather whilst simultaneously creating a dramatic, or discreet, façade. This can either be of a seamless appearance without visible joins or with defined folded intersections creating a strongly ribbed effect.

Cladding does not need to be a solid material but can be created from perforated metal or mesh. Using non-solid materials means that the cladding can perform functions such as solar-shading and screening.

Interior cladding can take the form of panelling, whether single or abutting panels, and can be formed from wire mesh, perforated material, laser-cut or solid metal.

Where interior cladding is used:-

Reception areas: providing a durable finish for high-traffic areas in office and hotel buildings.

Restaurants: being a relatively simple way to transform the look of a space with a new texture and finish.

Transport hubs: a metal-clad wall will be the most durable application for high-traffic areas, retaining its appearance as well as resisting wear and tear.

Working with the architect, engineer and designer – fabrication and installation

As architectural metalwork experts John Desmond Ltd is used to working closely with architects and designers to achieve the style and impact they aim to achieve with their interior and exterior cladding designs.

Working in a range of metals, coatings and finishes we like to be introduced to the project at an early stage to advise in the most suitable and cost-effective cladding materials for the project.

Our expertise in materials and finishes often means we can advise and supply materials that achieve the look of a solid metal, such as bronze but that are much lighter in weight, more responsive to being worked, with superior aesthetic results, and are less expensive.

Access is often restricted on central city and transport projects so cladding can be created in modular form in our workshop and assembled on site saving working space and time on site.

Working with cladding design and installation companies – providing specialist materials and finishes

John Desmond Ltd work closely with specialist cladding companies providing support services, V-grooved metalwork and distinctive materials and finishes.

John Desmond extends a cladding system specialist’s product range through the provision of multiple options on metal treatment, finish and colour for cladding panels, fixings, glazing bars and bracketry.

Contact Alex Pashouros, Project Manager, to discuss your requirements on 0203 325 9365 or email [email protected]

A selection of John Desmond Ltd projects utilising interior and exterior cladding

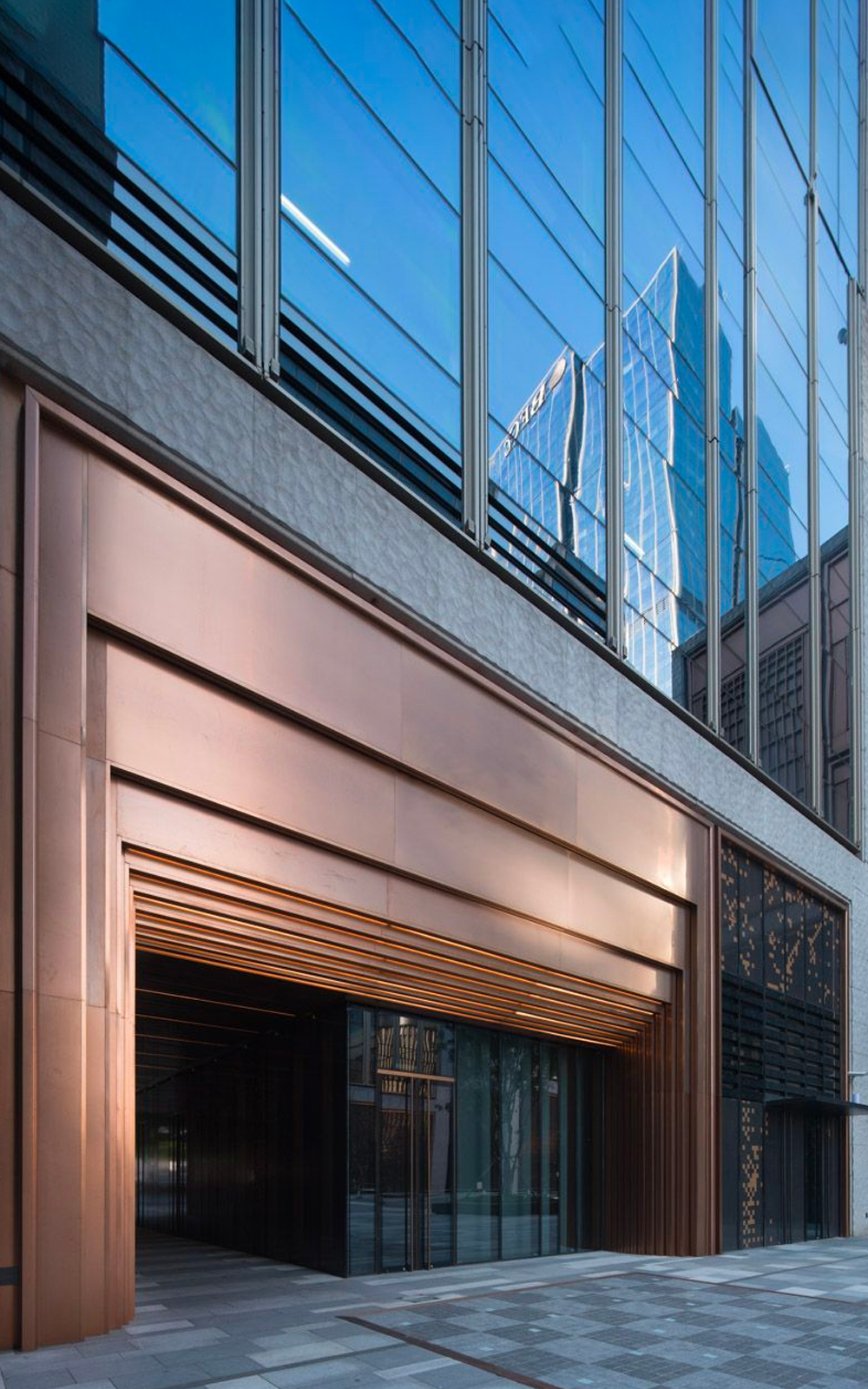

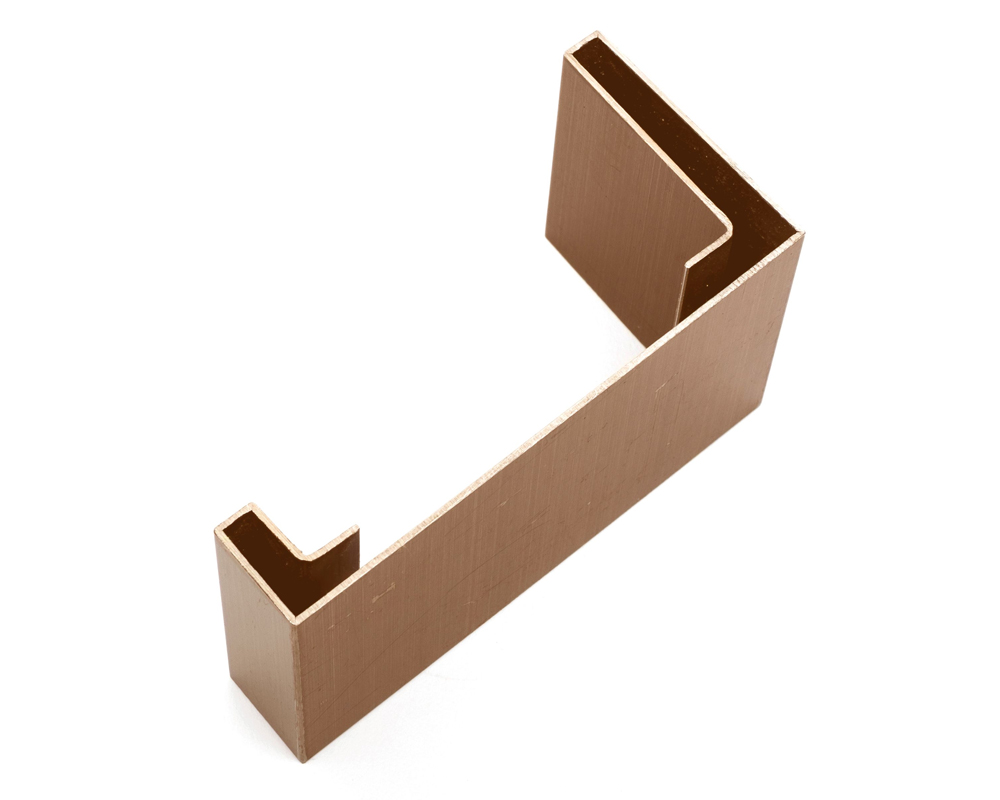

Stepped door entry at the Shanghai Bund Financial Centre in PVD coloured stainless steel, Rose Gold Vibration.

Architects: Foster & Partners; Heatherwick Studio

PVD coloured stainless steel:: Double Stone Steel in partnership with John Desmond Ltd.

The Rose Gold PVD emits the sheen and solid appeal of bronze without the expense. The V-grooved and folded rebates give a sharp stepping and further give the impression of solid material.

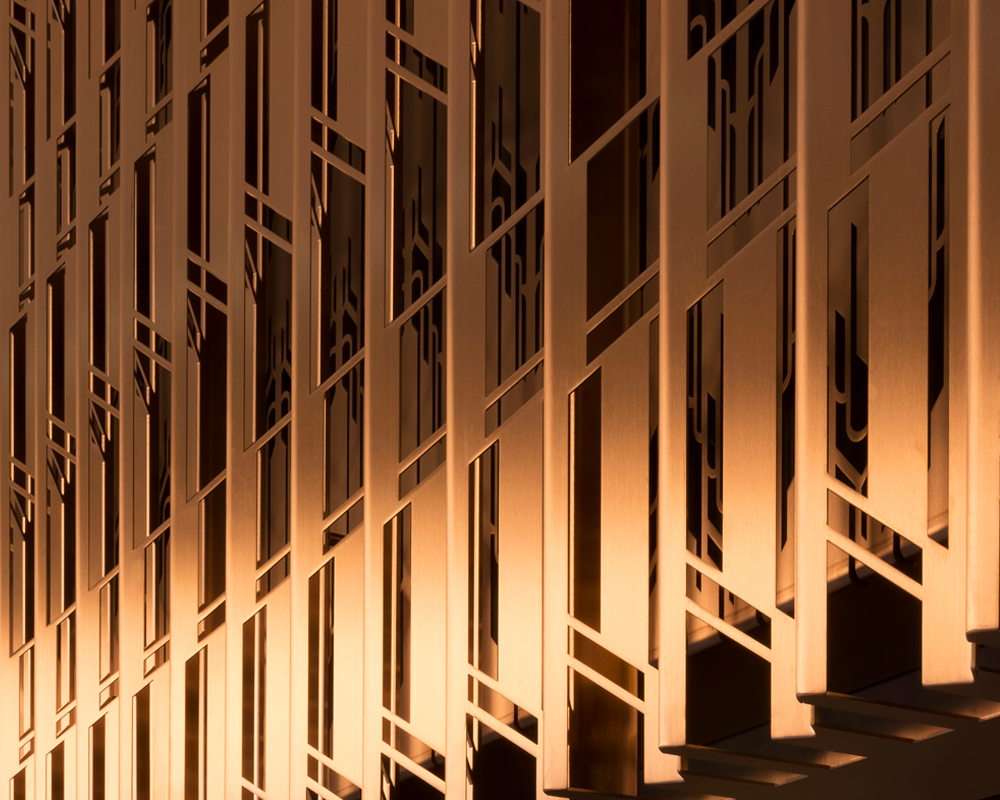

A close-up view of the façade of the Shanghai Bund Arts and Cultural Centre made from PVD stainless steel in Rose Gold Vibration.

Architects: Foster & Partners; Heatherwick Studio

PVD: Double Stone Steel in partnership with John Desmond Ltd.

Prior to being specified the architectural team put the PVD stainless steel through vigorous testing for multiple potential damaging agents including salt vapour, detergent and boiling water.

Roof extension to the Aberdeen Art Gallery clad in PVD coloured stainless steel in Copper. In 2021 the Art Gallery won the Andrew Doolan Best Building in Scotland Award as well as an RIBA National Award.

Restoration, modernisation and new-build extension to Aberdeen Art Gallery, Schoolhill, Aberdeen, AB10 1FQ.

Architects: Hoskins Architects

Contractor: McLaughlin & Harvey

The specification of the Copper PVD with a strong vertical delineation references the perpendicular classicism of the original building whilst creating a completely modern element to the architecture.

Tapered column in PVD coloured stainless steel, Chocolate, V-Grooved and folded to appear as solid bronze.

Office building, 15 Fetter Lane, EC4A, London.

Architects: McBains Cooper

Client: British Steel Pension Fund Trustees Ltd

Fit-out: Nucom Interiors

Canopy, column and Brise Soleil fabricated in PVD coloured stainless steel and installed by John Desmond Ltd.

PVD coloured stainless steel is easy to clean using a damp cloth making this finish a practical option for a high-traffic building entry point.

Narrow, stacked Bronze Brush PVD coloured stainless steel-clad bars with blackened ends create a feature wall at the rear of the reception area.

1 Broadgate Quarter, Snowden St, London, EC2A 2AW

Architects: John Robertson Architects.

Utilising bronze PVD, instead of brass, gives an established, timeless look without the weight and expense of using real bronze or brass. PVD was cut and folded using the V-grooving method to appear as solid metal.

Order a sample of PVD coloured stainless steel in Bronze

Undulating façade, columns and detailing in Double Stone Steel PVD coloured stainless steel Royal Gold Mirror.

Harvey Nichols retail department store, The Avenues, Kuwait.

Client: Four IV Interior Design

Architect: Gensler

Developer: Mabanee

A glitzy, up-market façade was specified and the appearance of real gold was achieved in line with the brand, for this luxury high-end store.

See more on the Harvey Nichols project

Order a sample of Royal Gold PVD coloured stainless steel, Mirror finish

Materials, finishes and coatings

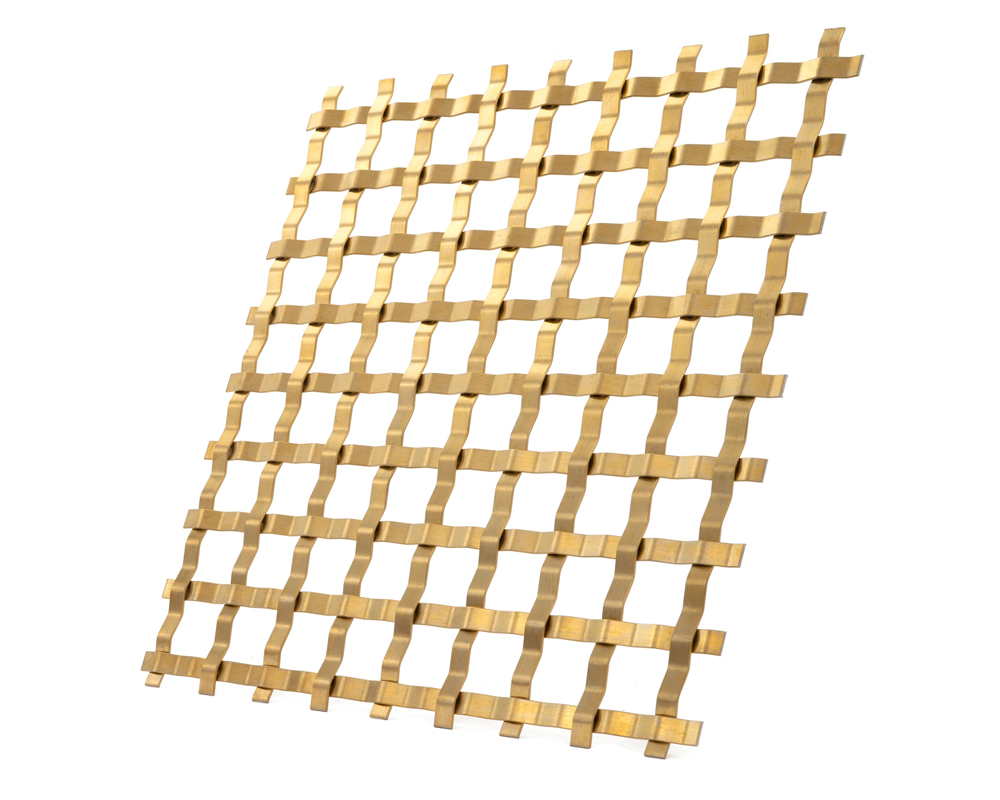

PVD coloured stainless steel architectural mesh

Stainless steel Architectural Mesh is a strong and relatively lightweight product specified for interior and exterior applications. Brass and copper mesh, for example, can be replicated through the PVD process with a resulting product that will not tarnish or age.

See a range of mesh designs and applications and PVD colourways

PVD coloured stainless steel

PVD coloured stainless steel is a sustainable alternative to anodising and electro-coating both of which involve chemical baths. The PVD process uses heat and gas and produces no chemical waste products.

Textured stainless steel

Textured stainless steel brings another dimension to specifying PVD coloured stainless steel. The range of embossed, surfaces provide tactile qualities as well as reflecting light in subtle ways which add to the creative possibilities when designing with this material.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel.

Cor-ten – Accelerated finish

Corten, also known as weathering steel, is designed to develop a rusty patina, making it corrosion-resistant and requiring no refinishing. John Desmond Ltd has developed a technique to expedite the patina formation process, enabling fabrication within commercial timescales.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel

Patinated Brass

Left untouched, all brass would develop into patinated brass. However ready-patinated brass, created by John Desmond Ltd, already has an aged, richly-toned surface. This finish is stabilised with the application of a natural sealant making it suitable for interior and exterior applications.

Contact Alex via [email protected] to ask about a Cor-ten finish for your project.

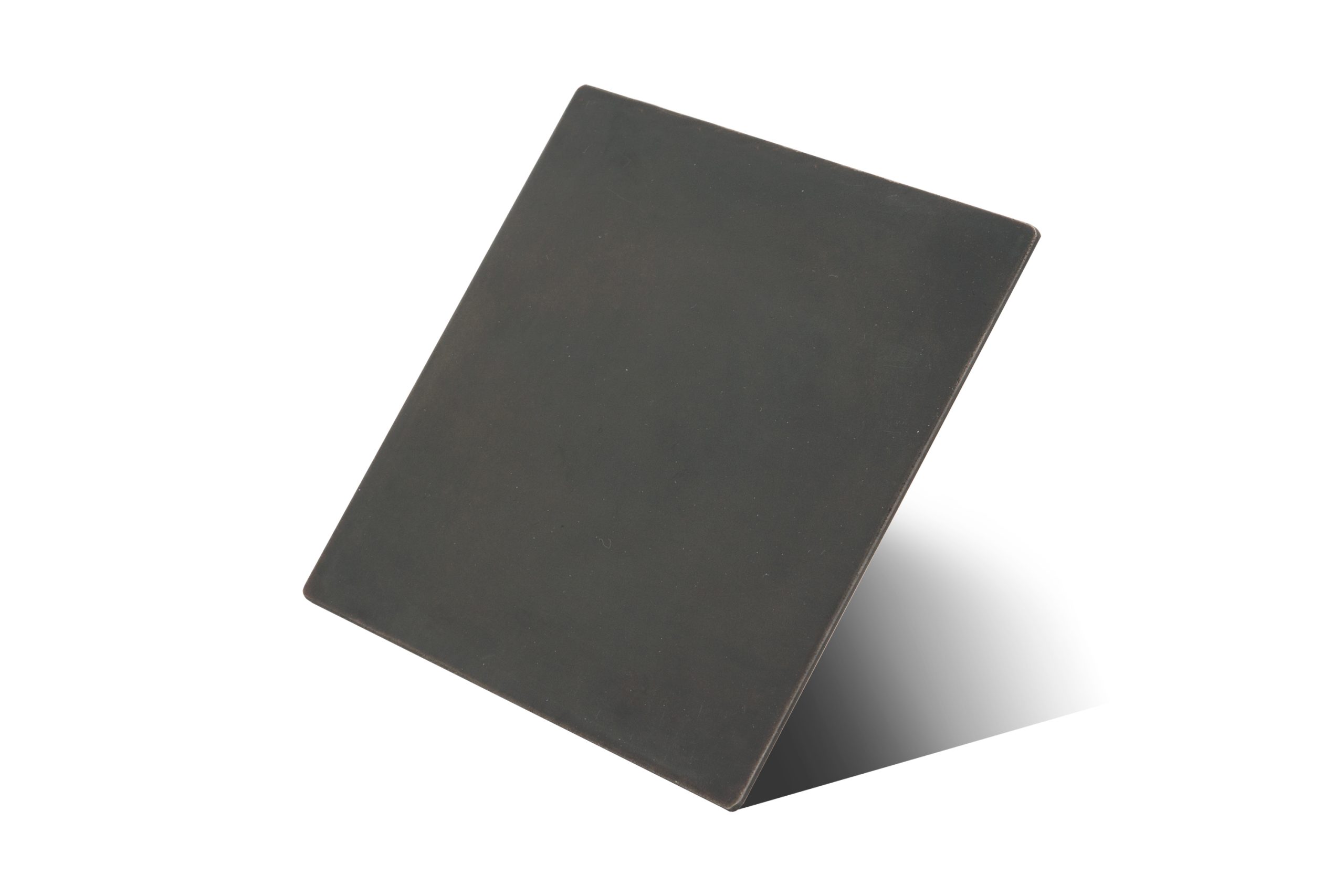

Blackened stainless steel

The blackening of stainless steel actually increases its corrosion-resistance however is mostly specified for its gleaming appearance not easily achieved through other methods. A natural wax finish is applied which maintains the burnished look yet allows the material to patinate over time.

See how blackened stainless steel creates a dramatic staircase at Google headquarters

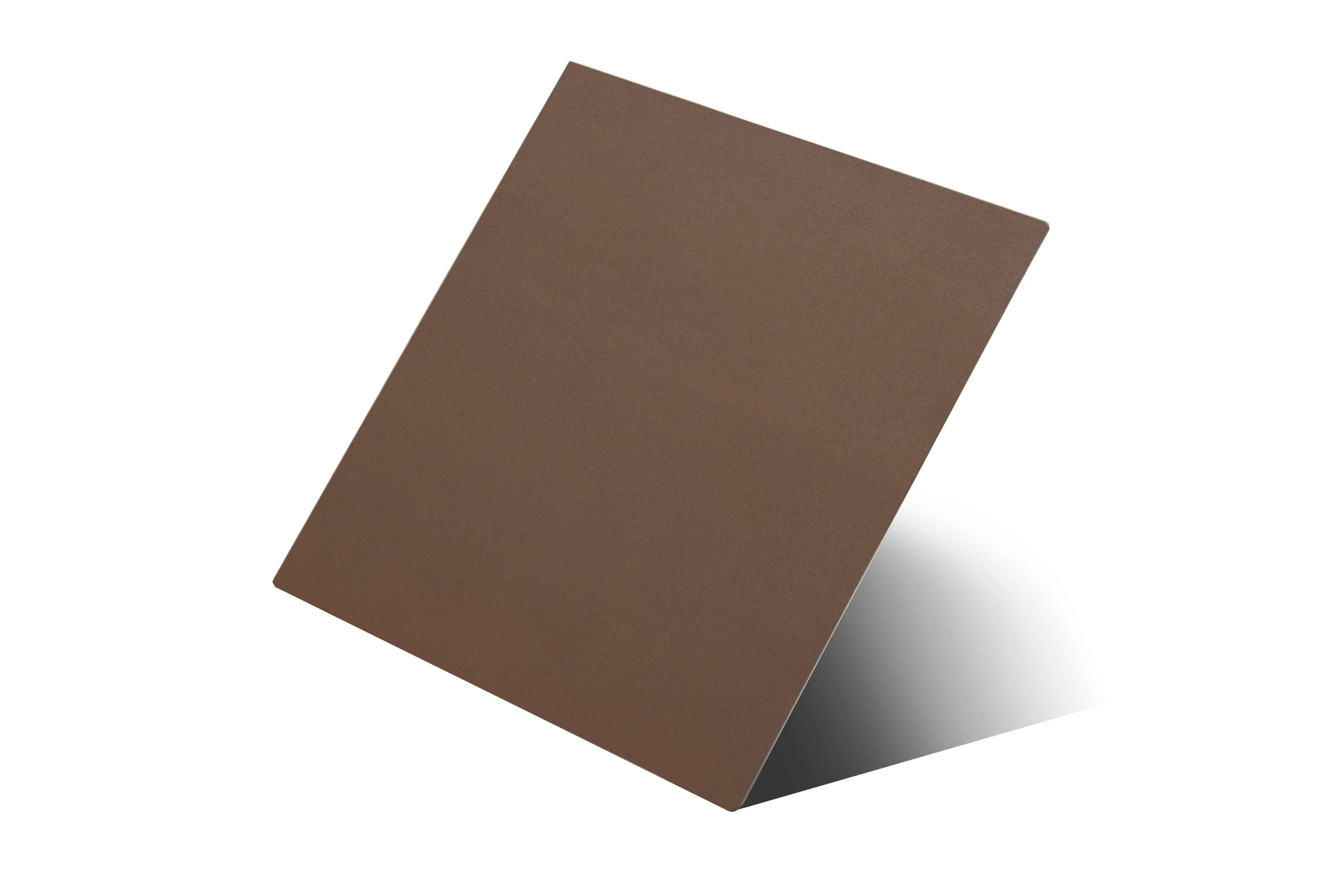

Marron powder-coat

The powder-coat colour Marron is an interesting extension to the range of John Desmond Ltd’s metal finishes. It has a bronze, metallic appearance and is a cost-effective way to achieve a rich, bronze finish for items such as planters.

Contact Alex via [email protected] to ask about Marron powder coat.

Vibration stainless steel

Vibration finish stainless steel is a versatile finish for stainless steel being non-directional and relatively non-reflective making it particularly suitable for exterior cladding. It is one of a range of finishes on stainless steel, including shot-peening and bead-blasting, offered by John Desmond Ltd.

See PVD coloured stainless steel in Vibration and other finishes and order a sample.

Shot-peened stainless steel

Shot-peening, also known as sand-blasting, increases the longevity of steel and is commonly used for aeronautical components. However it also has an interesting and versatile non-directional appearance and is consequently specified for its aesthetic as well as its relative non-reflectancy.

Find out more about shot-peened steel and stainless steel, call Matt on 020 8946 8295

Anodised aluminium

Aluminium is a lightweight, corrosion-resistant and relatively inexpensive material. Through the process of anodising aluminium can be transformed into a range of around ten coloured finishes.With the application of powder-coating an extensive range of metallic and solid colours can be achieved.

See the domed gold anodised aluminium ceiling at Wood Lane Underground Station

Laser-cutting

The laser-cutting of stainless steel, combined with PVD colouring and V-grooving provides a multitude of creative possibilities for interior and exterior applications. Laser-cutting can be used to create intricate patterns for items such as cladding, screens, balconies, balustrades and planters.

V-grooving and folding

V-Grooving and folding of specialist or laser-cut material adds to the design possibilities for very finely crafted and intricate metalwork.

This process facilitates sharp bends which replicate solid bar material whilst being lighter, less expensive and easier to work.