Elevators and escalators

The Gaslight Building, 29 – 35 Rathbone Street, London.

Developer I.S.A Holdings

Interior architecture and design: bureau de change design office

Architects: dMFK Architects

Laser-cut PVD coloured stainless steel in custom Bronze Hairline for stairs, lift core and architectural detailing by Double Stone Steel in partnership with John Desmond Ltd.

Photography by Gilbert McCarragher

Elevators and elevator lobbies

Elevators and elevator lobbies provide an opportunity to create the atmosphere, or brand, of the building and denote the status of its occupants and visitors.

It is not surprising that developers, designers and landlords pay considerable attention to the style and detail of their elevators and lobbies.

Whether it is an upgrade or new installation all elevator interiors must be practical and durable. For designers wishing to achieve a stand-out impression – as an elevator cab is always the same shape and format – then this is where the special focus on materials and finishes is so crucial.

You will see in some of the examples shown below how the use of architectural mesh, laser-cutting, V-grooving and combining really unusual PVD colours has created highly distinctive cab interiors and elevator lobby design schemes.

Working with the architect, engineer and designer – fabrication and installation

As architectural metalwork experts John Desmond Ltd is used to working closely with architects and designers to achieve the style and impact they aim to achieve with elevator cab interiors and the elevator lobby design scheme.

Working in a range of metals, coatings and finishes we like to be introduced to the project at an early stage to advise on the most suitable and cost-effective materials for the project. We also liaise with your elevator manufacturer and installer to achieve the design that you want.

Our expertise in materials and finishes often means we can advise and supply materials that achieve the look of a solid metal, such as bronze but that are much lighter in weight, more responsive to being worked, with superior aesthetic results, and are less expensive.

Working with elevator specialists

John Desmond Ltd work closely with specialist elevator design, manufacture and refurbishment companies providing support services, V-grooved metalwork and distinctive materials and finishes.

We help the elevator manufacturer create the style that the architect and designer have specified through a detailed review of the materials specified and advising on alternative materials that will achieve the finished look.

Obviously the cost of materials and their weight are important factors in the creation of an elevator interior and being able to advise on, and supply, lighter-weight alternatives that are less costly yet deliver the aesthetic impact that the designers want is one of our key services.

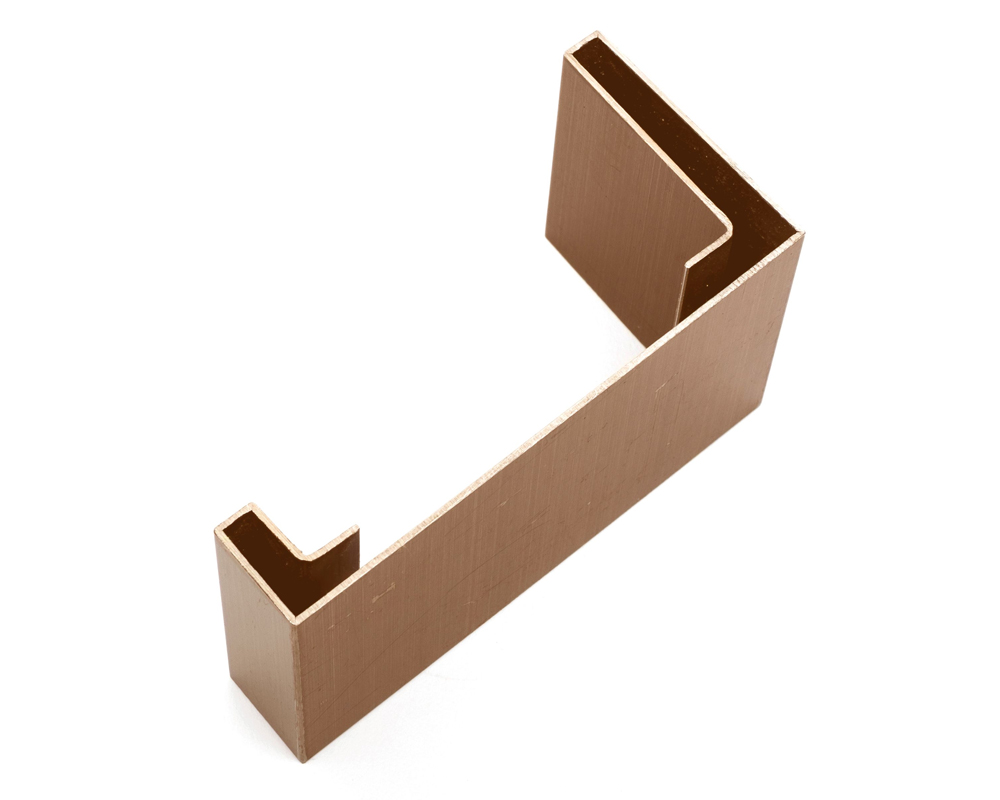

Being able to V-groove and fold these materials to create very slim architraves and profiles, avoiding the use of heavy, expensive solid bar material is again a core part of our offer to elevator designers and manufacturers.

Contact Alex Pashouros, Project Manager, to discuss your requirements on 0203 325 9365 or email [email protected]

A selection of John Desmond Ltd elevators and escalators projects

Elevator lobby with door skins, overhead panel and architrave in V-Grooved PVD coloured stainless steel Chocolate Vibration.

Fenman House, Apartment Building, 9 Handyside St, King’s Cross, London N1C 4AY.

Building design: Maccreanor Lavington Architects

Interiors: Johnson Naylor Architects

Developer: Argent

Fabrication, V-Grooving and folding of stainless steel: John Desmond Ltd.

The original specification was for brass copper patinated to a bronze finish however this was both very costly and a heavy material. The PVD coloured stainless steel provided a similar rich hue and could be sharply folded, using the V-grooving process, to create the look of solid metal without the weight.

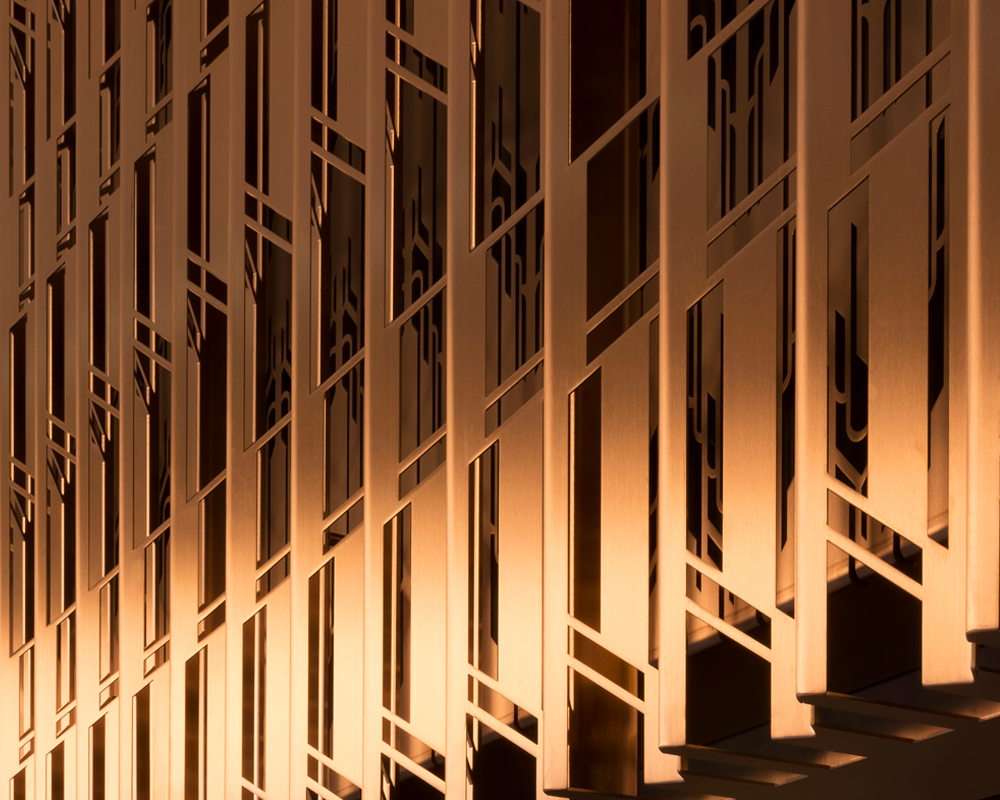

Laser-cut PVD coloured stainless steel in custom Bronze Hairline for stairs, lift core and architectural detailing.

The Gaslight Building, 29 – 35 Rathbone Street, London.

Developer: I.S.A Holdings

Interior architecture and design: bureau de change design office

Architects: dMFK Architects

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

Photography by Gilbert McCarragher

Whilst developing the original concept of having bronze for the lift core material it was found that it cracked when bent or folded. PVD stainless steel was introduced as a material that can successfully be worked and shaped whilst retaining the desired rich, bronze hue.

Contact Matt, Estimating & Production Manager on [email protected] to discuss your PVD stainless steel requirements.

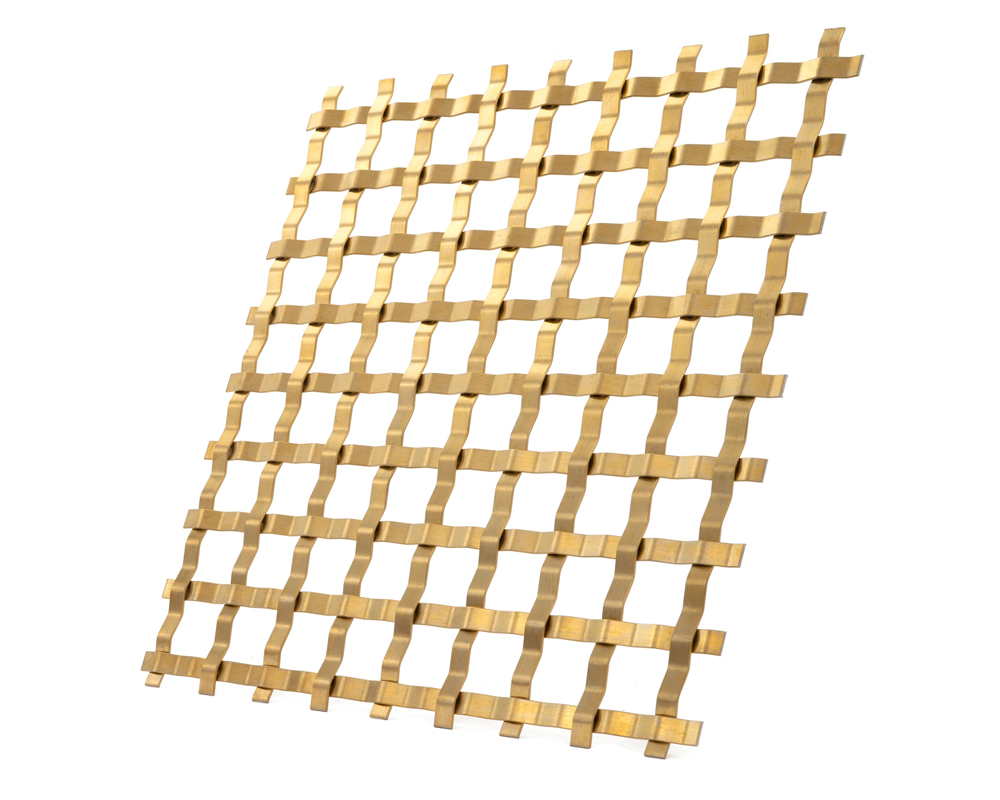

Architectural mesh elevator cab shell walls in bronze.

166 Geary Street, The Grace Building, San Francisco

Project Designer: Unique Elevator Interiors

Architectural mesh: Banker Wire

Along with the renovation of 166 Geary Street, also known as the 1907 Grace Building, the elevators were an important and highly visible element that needed to be upgraded. The aim of the improvements was to modernise but keep a timeless, classic feel in keeping with the history of the building.

The walls of the cab are created from a woven wire mesh in bronze with a distinct squared-off “boss” at each junction. The mesh elevator panels are slightly transparent, having a 9.2% open area, and allow exciting glimpses through to the workings of the elevator shaft as well as creating an airy feel to the cab interior.

PVD coloured stainless steel in Nickel Hairline and Chrome Vibration for elevator cab interior with Brass Mirror detailing and Chocolate Vibration frieze and kickplate.

Krungsri Ploenchit Tower, Thailand.

Elevator: A global elevator brand

Architecture and design: Palmer & Turner, Hong Kong

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

The cab interior has side panels in PVD coloured stainless steel in Nickel Hairline with narrow vertical bars in Brass Mirror PVD that provide a decorative element to the rear of the cab and an edging to the side panels. Overhead horizontal frieze sections and kickplates are in Chocolate PVD Vibration. The handrail is in PVD stainless steel in Chrome Brush.

Contact Matt to discuss your PVD stainless steel requirements [email protected].

PVD coloured stainless steel in Nickel Hairline and Chrome Vibration for elevator cab interior.

Krungsri Ploenchit Tower, Thailand.

Elevator: A global elevator brand

Architecture and design: Palmer & Turner, Hong Kong

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

The Ploenchit Tower is headquarters for the Krungsri group and with 39 storeys the elevator is an essential element. It also creates a focus for the core of the building with a streamlined, minimalist approach to the elevator cab, exterior and lobby design.

The elevator door skins and surround are in Nickel Brush PVD coloured stainless steel providing a very subtle counterpoint to the wall panelling in ecru reeded cladding.

Contact Matt to discuss your PVD stainless steel requirements [email protected].

Order samples of PVD stainless steel in Nickel Brush and Chrome Mirror

Elevator door skins in PVD coloured stainless steel in Nickel Brush with Brass Mirror edge detailing.

Krungsri Ploenchit Tower, Thailand.

Elevator: A global elevator brand

Architecture and design: Palmer & Turner, Hong Kong

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

The designers have created a calm and uplifting environment within the elevator and lobby with a soft palette of colours. The introduction of brass, chrome and chocolate accents (a deep bronze) might seem surprising however work charmingly together even where they intersect. The Chrome PVD handrail intersects with the Brass PVD strips and the Brass intersects with the Chocolate kickplate and frieze sections yet still convey a sense of unity as they harmonise within the overall design scheme.

Contact Matt to discuss your PVD stainless steel requirements [email protected]

Escalators in an Art Deco palette of almond gold and nickel bronze PVD coloured stainless steel with accompanying black and white detailing.

Renovated escalator hall, Knightsbridge store, London, UK.

Architect: Make Architects

PVD coloured stainless steel trims: John Desmond Ltd.

The durability – and “cleanability” of materials specified was an essential consideration in this London store with its high traffic of customers passing through the escalator hall for 11 hours every day.

The architects specified additional microns of PVD coating of the stainless steel to create a higher level of durability. The fact that the PVD can be wiped clean of fingerprints with a damp cloth was also key to its being deemed ideal for this location and application.

Exterior cladding panels to lift shaft in double layers of Amron Rigid Woven Architectural mesh M22-28 and I-188 in Antique Bronze.

Hide Restaurant, 85 Piccadilly, London.

Collaboration project between Hedonism Wines and Chef Ollie Dabbous.

Client & Restaurateurs: Evgeny Chichvarkin and Tatiana Fokina

Interior designers: These White Walls

Architectural consultancy: Lusted Green

Staircase: Atmos Studio

One way of creating a distinctive look to an elevator shaft exterior is to layer different finishes. Here a patinated brass shaft cladding has been overlaid with copper architectural mesh broken into irregular panels with a chunky V-grooved frame again in irregular dimensions and profiles. The result is a retro-industrial appearance and creates quite an exciting approach to the lift.

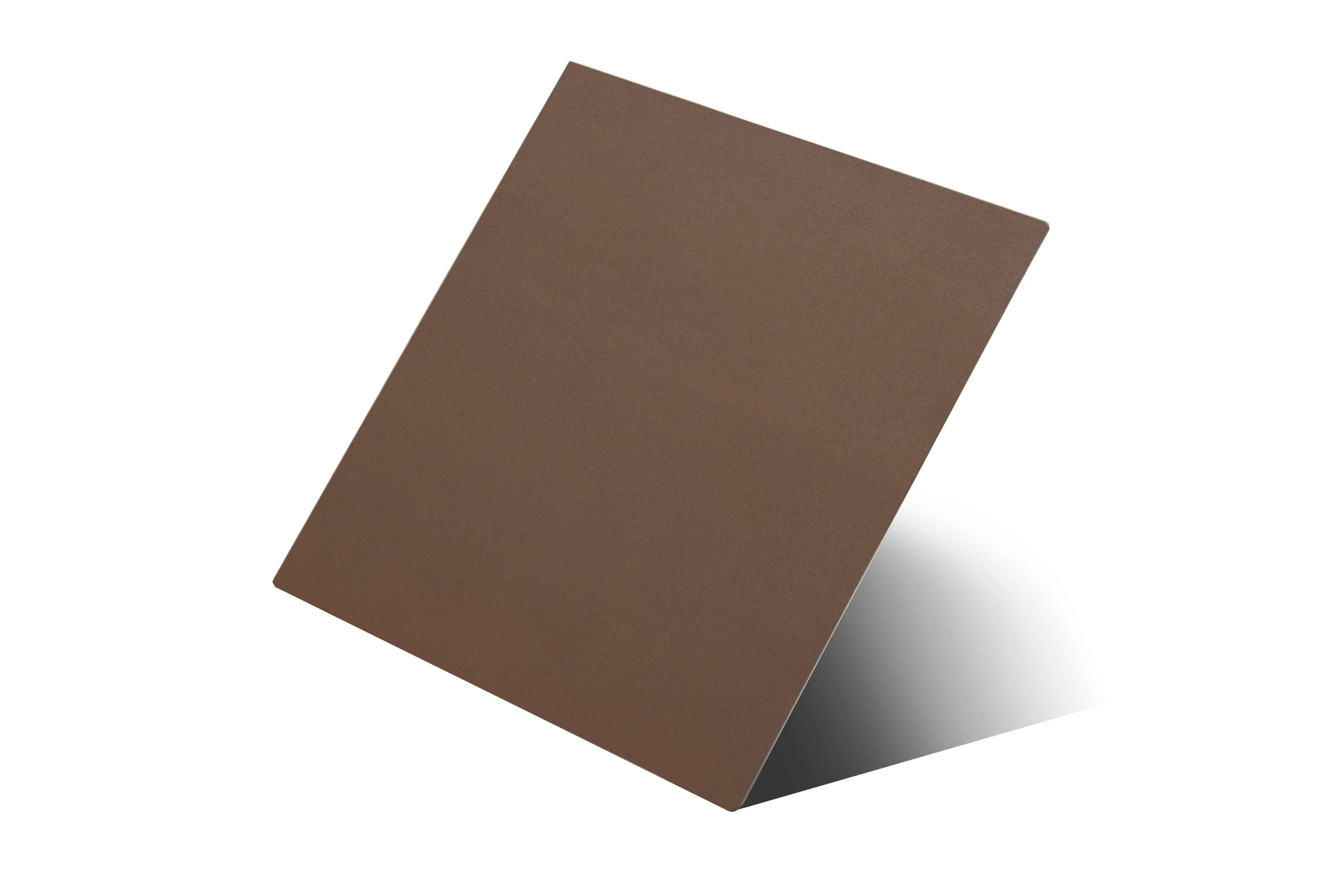

Elevator door skins, overhead and side panels in PVD coloured stainless steel Chocolate Vibration.

Axtell House, 23-24 Warwick St, Soho, London W1B 5NQ

Renovated office building

Architects: Darling Associates

Client: E&A Property Investment Company

PVD coloured stainless steel: John Desmond Ltd

The star of the show in this stair and elevator lobby is the intricate laser-cut balustrading for the staircase. However the gleaming bronze PVD elevator cladding creates an elegant foil to the sophisticated tracery of the staircase design. The designer was inspired to not try to make a match but to allow the two strong elements to stand separately, each with their own statement, within the space.

Contact Alex on [email protected] or call 020 8946 8295 to discuss materials for your elevator or stair design.

Elevator cab with laser-cut PVD stainless steel backlit panel in PVD coloured stainless steel Bronze Vibration, side panels in Champagne Vibration and handrail inset section in Bronze Vibration.

Guangzhou Infinitus Plaza Building

Architecture and design: Zaha Hadid Architects

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

Infinitus is a herbal health company so the elevator design needed to be calm as well as inspiring and promote feelings of wellness.

The warm tones of Bronze and Champagne PVD stainless steel have a cocooning effect and with all PVD surfaces able to be cleaned with the wipe of a damp cloth are also a highly practical choice.

Contact Matt, Estimating & Production Manager to discuss your PVD stainless steel requirements [email protected]

Order samples of PVD stainless steel in Bronze and Champagne Vibration

Elevator cab with vertical curved radius corner sections in PVD coloured stainless steel Chocolate Vibration and wall panels in PVD coloured stainless steel Nickel Vibration. Rear wall panel has shadow-gap detailing created by V-grooving.

Hongqi headquarters, Changchun, Jilin , China

Architecture: Woods Bagot

PVD coloured stainless steel by Double Stone Steel in partnership with John Desmond Ltd.

Hongqi are a break-away luxury car brand and the elevator interior certainly reflects the sleek looks of a luxury saloon. The combination of the Chocolate and Nickel are understated yet create a striking cab interior. The V-grooving detail at the rear of the cab has allowed the lines of the horizontal handrail inset and vertical panels to be continued in a subtle way.

Contact Matt, Estimating & Production Manager to discuss your PVD stainless steel requirements [email protected]

Order samples of PVD stainless steel in Chocolate and Nickel Vibration

Elevator lobby with door skins, overhead panel and architrave in V-Grooved PVD coloured stainless steel Chocolate Vibration.

Fenman House, Apartment Building, 9 Handyside St, King’s Cross, London N1C 4AY.

Building design: Maccreanor Lavington Architects

Interiors: Johnson Naylor Architects

Developer: Argent

Fabrication, V-Grooving and folding of stainless steel: John Desmond Ltd.

Instead of a light, bright and gleaming corporate-style elevator lobby Johnson Naylor have created a rich, moody atmosphere with dark bronze and wenge timber. The use of the very dark, grained wenge as lobby panelling is seamlessly echoed through the deep bronze of the elevator door skins, overhead panelling and architrave.

Contact Alex on [email protected] or call 020 8946 8295 to discuss materials for your elevator or stair design.

Materials, finishes and coatings

PVD coloured stainless steel architectural mesh

Stainless steel Architectural Mesh is a strong and relatively lightweight product specified for interior and exterior applications. Brass and copper mesh, for example, can be replicated through the PVD process with a resulting product that will not tarnish or age.

See a range of mesh designs and applications and PVD colourways

PVD coloured stainless steel

PVD coloured stainless steel is a sustainable alternative to anodising and electro-coating both of which involve chemical baths. The PVD process uses heat and gas and produces no chemical waste products.

Textured stainless steel

Textured stainless steel brings another dimension to specifying PVD coloured stainless steel. The range of embossed, surfaces provide tactile qualities as well as reflecting light in subtle ways which add to the creative possibilities when designing with this material.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel.

Cor-ten – Accelerated finish

Corten, also known as weathering steel, is designed to develop a rusty patina, making it corrosion-resistant and requiring no refinishing. John Desmond Ltd has developed a technique to expedite the patina formation process, enabling fabrication within commercial timescales.

Contact Matt, Estimating & Production Manager to ask about textured stainless steel

Patinated Brass

Left untouched, all brass would develop into patinated brass. However ready-patinated brass, created by John Desmond Ltd, already has an aged, richly-toned surface. This finish is stabilised with the application of a natural sealant making it suitable for interior and exterior applications.

Contact Alex via [email protected] to ask about a Cor-ten finish for your project.

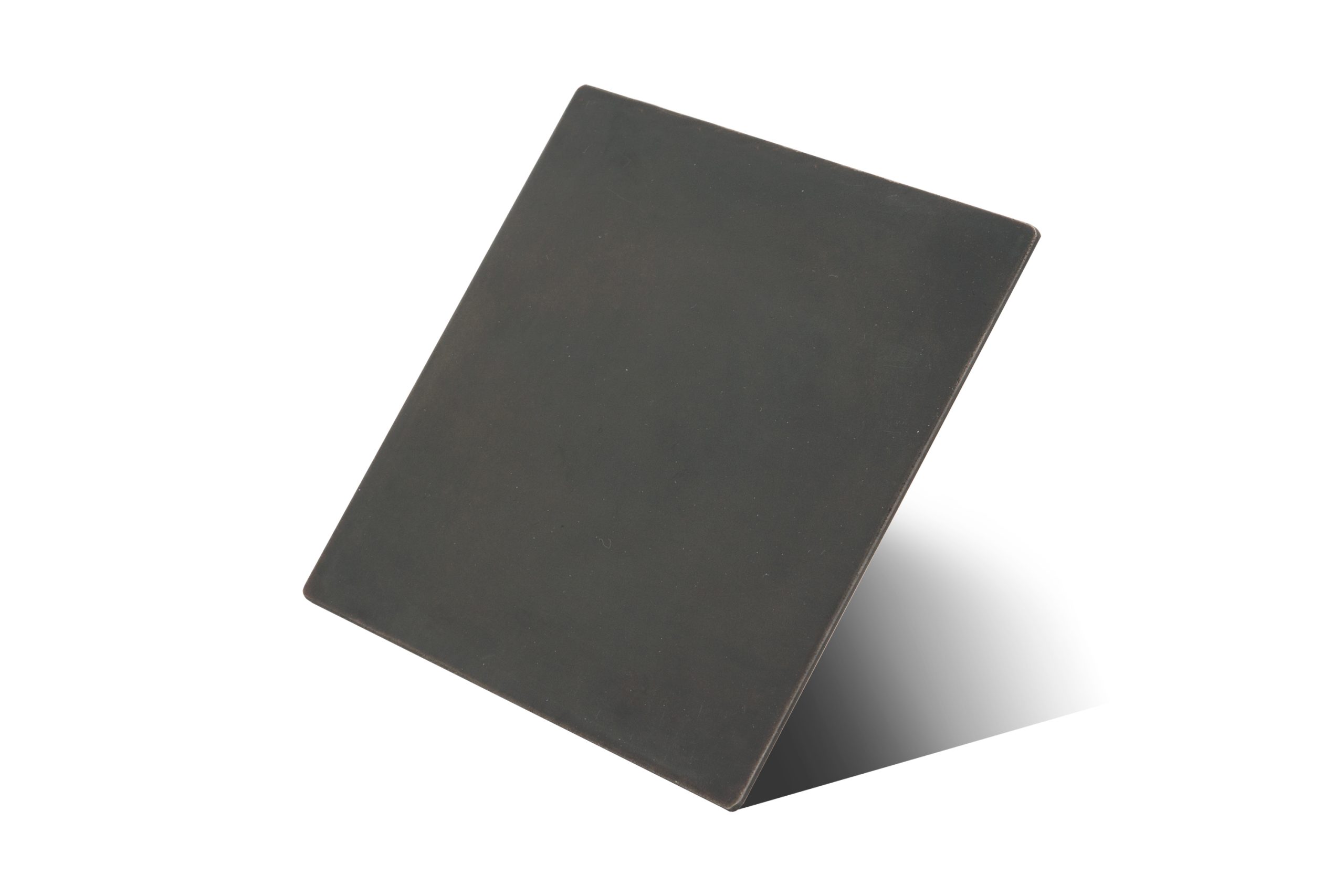

Blackened stainless steel

The blackening of stainless steel actually increases its corrosion-resistance however is mostly specified for its gleaming appearance not easily achieved through other methods. A natural wax finish is applied which maintains the burnished look yet allows the material to patinate over time.

See how blackened stainless steel creates a dramatic staircase at Google headquarters

Marron powder-coat

The powder-coat colour Marron is an interesting extension to the range of John Desmond Ltd’s metal finishes. It has a bronze, metallic appearance and is a cost-effective way to achieve a rich, bronze finish for items such as planters.

Contact Alex via [email protected] to ask about Marron powder coat.

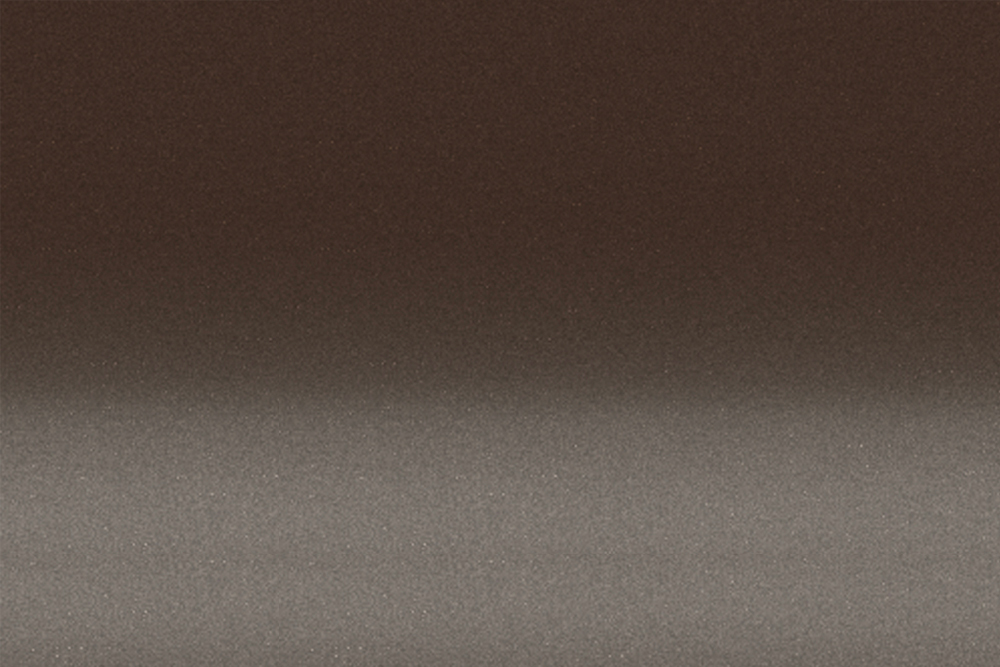

Vibration stainless steel

Vibration finish stainless steel is a versatile finish for stainless steel being non-directional and relatively non-reflective making it particularly suitable for exterior cladding. It is one of a range of finishes on stainless steel, including shot-peening and bead-blasting, offered by John Desmond Ltd.

See PVD coloured stainless steel in Vibration and other finishes and order a sample.

Shot-peened stainless steel

Shot-peening, also known as sand-blasting, increases the longevity of steel and is commonly used for aeronautical components. However it also has an interesting and versatile non-directional appearance and is consequently specified for its aesthetic as well as its relative non-reflectancy.

Find out more about shot-peened steel and stainless steel, call Matt on 020 8946 8295

Anodised aluminium

Aluminium is a lightweight, corrosion-resistant and relatively inexpensive material. Through the process of anodising aluminium can be transformed into a range of around ten coloured finishes.With the application of powder-coating an extensive range of metallic and solid colours can be achieved.

See the domed gold anodised aluminium ceiling at Wood Lane Underground Station

Laser-cutting

The laser-cutting of stainless steel, combined with PVD colouring and V-grooving provides a multitude of creative possibilities for interior and exterior applications. Laser-cutting can be used to create intricate patterns for items such as cladding, screens, balconies, balustrades and planters.

V-grooving and folding

V-Grooving and folding of specialist or laser-cut material adds to the design possibilities for very finely crafted and intricate metalwork.

This process facilitates sharp bends which replicate solid bar material whilst being lighter, less expensive and easier to work.